Dribble Bar Applicators

Delivering slurry where it is needed

MULTI-AWARD WINNING DRIBBLE BAR SYSTEMS

Delivering slurry where it is needed

The essence of successful slurry/manure application is to deliver the right amount directly onto the soil, with minimal disruption to plant matter and soil structure.

This is where we excel.

SlurryKat is a world leader in the development and manufacture of high end dribble bar slurry/manure dispersal systems. Specifically designed to be controlled by one operator, SlurryKat’s entire range of umbilical slurry/manure systems and dribble bars has been tried and tested in Ireland, one of the toughest farming environments in Europe.

Available for use all year round, and with any crops, SlurryKat dribble bars achieve a uniform spread of slurry/manure, with minimal plant contamination. As a result, fertiliser costs could be reduced by up to 80%.

See our NEW 18m Premium Plus™ Duo Dribble Bar HERE

Delivering slurry where it is needed

The essence of successful slurry/manure application is to deliver the right amount directly onto the soil, with minimal disruption to plant matter and soil structure.

This is where we excel.

SlurryKat is a world leader in the development and manufacture of high end dribble bar slurry/manure dispersal systems. Specifically designed to be controlled by one operator, SlurryKat’s entire range of umbilical slurry/manure systems and dribble bars has been tried and tested in Ireland, one of the toughest farming environments in Europe.

Available for use all year round, and with any crops, SlurryKat dribble bars achieve a uniform spread of slurry/manure, with minimal plant contamination. As a result, fertiliser costs could be reduced by up to 80%.

See our NEW 18m Premium Plus™ Duo Dribble Bar HERE

The 15m dribble bar is the best spreading dribble bar we have ever used, in two full seasons we have spread over 30 million gallons and the macerators have not been touched or serviced and are still working perfectly, we very rarely see any blockages on any of the delivery hoses.

All of our dribble bars are CE approved and are available in widths from 7.5 metres up to 24 metres. So whether you are an independent farmer or a large scale contractor, SlurryKat has a system to meet your needs.

Dribble Bar Range

Super-flow™ 40mm slurry delivery hoses on all our units...

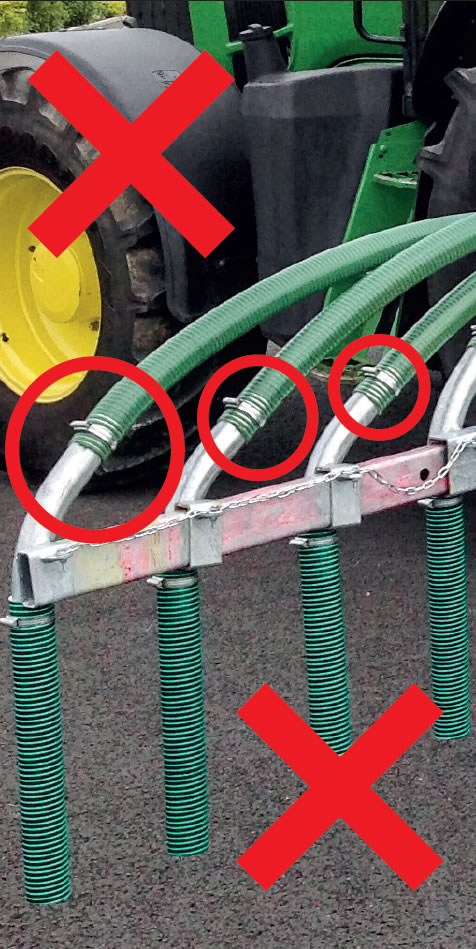

Competitors 50mm hoses c/w internal steel tubes which causes blockages

On all SlurryKat Dribble Bar & Trailing Shoe spreading systems we only use 40mm internal diameter specially manufactured delivery hoses. When SlurryKat first pioneered Dribble Bars back in 2007, we started with 50mm delivery hoses only to experience problems with blockages, flow rates and overall spreading performance.

Through in-field testing since 2007 our extensive contracting division has clearly proven that 40mm hoses boast much enhanced performance, trouble free blockages and enhanced environmental benefits despite confusing myths from other manufacturers.

Our unique Super-flow™’ design has 40mm delivery hoses which are inserted directly into 50mm drop hoses. These connections are retained with a patented clamping bracket (see photo opposite) which means that when the slurry leaves the 38mm outlets of the distributor head(s) there is nothing to restrict the slurry flow all the way until it leaves the machine to drop effortlessly to the ground.

Competitor machines (example image left) use 50mm hoses with internal steel tube connections. These internal steel connections not only corrode very rapidly after the first few months of operation but also massively restrict the flow by snagging with silage/ straw fibres on the inside of the PVC hoses.

Our in-depth trials have also proved that 50mm hoses resulted in increasingly messy “splashing” leading to much less precise delivery of slurry to the ground.

As we say “there is no substitute for experience”

Through in-field testing since 2007 our extensive contracting division has clearly proven that 40mm hoses boast much enhanced performance, trouble free blockages and enhanced environmental benefits despite confusing myths from other manufacturers.

Our unique Super-flow™’ design has 40mm delivery hoses which are inserted directly into 50mm drop hoses. These connections are retained with a patented clamping bracket (see photo opposite) which means that when the slurry leaves the 38mm outlets of the distributor head(s) there is nothing to restrict the slurry flow all the way until it leaves the machine to drop effortlessly to the ground.

Competitor machines (example image left) use 50mm hoses with internal steel tube connections. These internal steel connections not only corrode very rapidly after the first few months of operation but also massively restrict the flow by snagging with silage/ straw fibres on the inside of the PVC hoses.

Our in-depth trials have also proved that 50mm hoses resulted in increasingly messy “splashing” leading to much less precise delivery of slurry to the ground.

As we say “there is no substitute for experience”

This lead to an increased surface area and exposure to the air resulting in significant ammonia and nutrient losses and lower crop performance than compared to 40mm diameter hoses.

30 YEARS OF SLURRY HANDLING EXPERIENCE Less Fuel, Less Compaction & More Productivity

Information on specifications, prices and lead times can also be obtained from your nearest SlurryKat Dealer. View our Dealer Locator.